-

Contact Us

|

-

WeChat

wechat:569035139 Contact Us

wechat:569035139 Contact Us

ONLINE INQUIRY

ONLINE INQUIRY

Solution

Solution

Online ordering

Online ordering

Single production

Single production

logistics

logistics

After Sales

After Sales

return visit

return visit

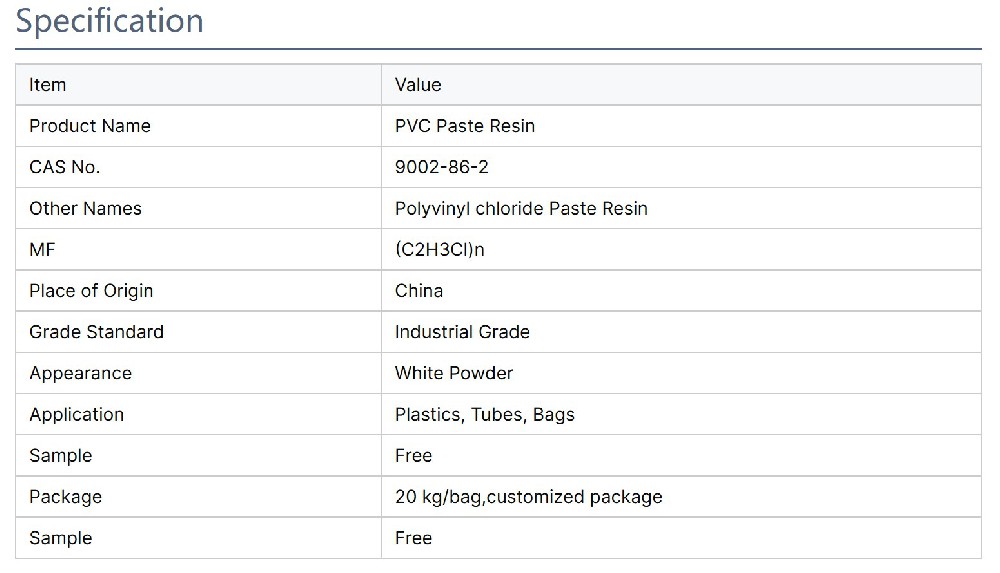

PVC paste resin (PVC) paste resins, as the name implies, are mainly applied in the form of a paste, which is often referred to as a plasticized paste, a unique liquid form of PVC plastic in its unprocessed state. Paste resins are often produced by emulsion and micro-suspension methods.Due to its fine particle size, PVC paste resin has a talc-like texture and is immobile. PVC paste resin is mixed with plasticizers and then stirred to for···...

View details

Microsuspension polyvinyl chloride paste resin(1) NaturePVC paste resin is a vinyl chloride homopolymer produced by the micro-suspension process, which is mixed with plasticizer and other processing AIDS during processing to form a dispersion paste, so it is called paste resin or paste resin.(2) SpecificationsTPM-31, whose polymerization degree is 1230 ~ 1430;(3) UsePVC paste resin is mainly used for processing coated artificial leather···...

Epoxidized soybean oil is a widely used non-toxic and odorless plasticizer and stabilizer for polyvinyl chloride and neoprene. It has good stability to light and heat, good compatibility, low volatility and migration. Small, it can absorb the hydrogen chloride released by the polyvinyl chloride resin during the decomposition, and can be compatible with the polyvinyl chloride, which is of great significance for improving the physical pro···...

Unfortunately, no plasticizer is perfect, so let's not just focus on the shortcomings of plasticizers.For example, DBP has an excellent plasticizing effect, but the flash point is low, and it is very easy to appear smoke during processing. Perhaps the following solutions can be considered: First, reduce the mold temperature, or add a little DOP to increase the flash point.The use of DBP for shoe materials is to take a fancy to its f···...